ExOne Scout

ExOne

ExOne GmbH

Industry

Additive Manufacturing

Gersthofen, Germany

codestryke solution

IoT Business Model Builder, Development

The initial situation

ExOne is the leading supplier for industrial 3D printing with sand. ExOne’s machines are used worldwide, for example in foundries. As part of an innovative digitalisation strategy, ExOne’s goal is to use automation, software and AI in such a way that profitable business models are created which achieve the highest possible benefit for the customer and end user.

S Max Pro

The latest model series from ExOne, called S Max Pro, already had all the necessary hardware to establish connectivity and make the data usable in the cloud. However, this data was not yet used in the initial situation.

The solution

Industrial IoT Business Model Builder

The first step was to check how a profitable business model with added value for the customer could be derived from the usable IoT data. For this purpose, ExOne conducted the codestryke IoT Business Model Builder Workshop.

This workshop concept brings together various stakeholders of the company from management, sales and development as well as from the customer side. Using pre-defined tools and methods, new business models and use cases are then identified and evaluated.

At the end of the workshop, a management decision template is created which serves to enable those responsible for the budget to make a well-founded decision.

ExOne Scout

ExOne has decided to implement the potential identified in the IoT Business Model Builder in the form of an app supplied with the machine. This app is available as ExOne Scout on the web as well as in the Apple and Google Play Store and is currently being used by customers internationally in 6 different languages.

Your benefits

AI-based optimisation of the process

A camera can be used to compare the printed sand layers with the loaded print job using AI. If the actual print deviates too much from the print job, either countermeasures can be taken in the process or the current print job can be cancelled to avoid rejects.

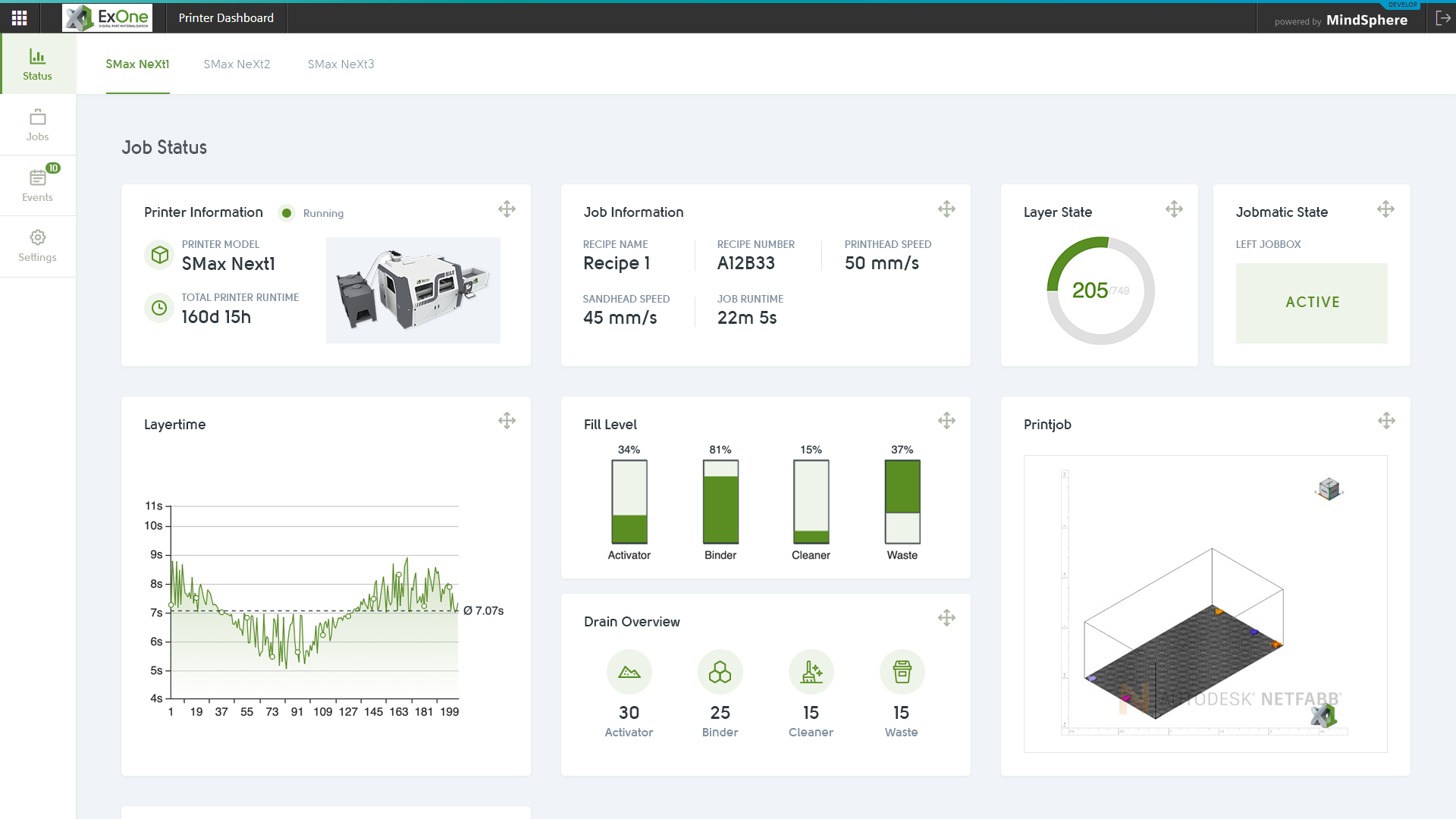

Simplify press monitoring

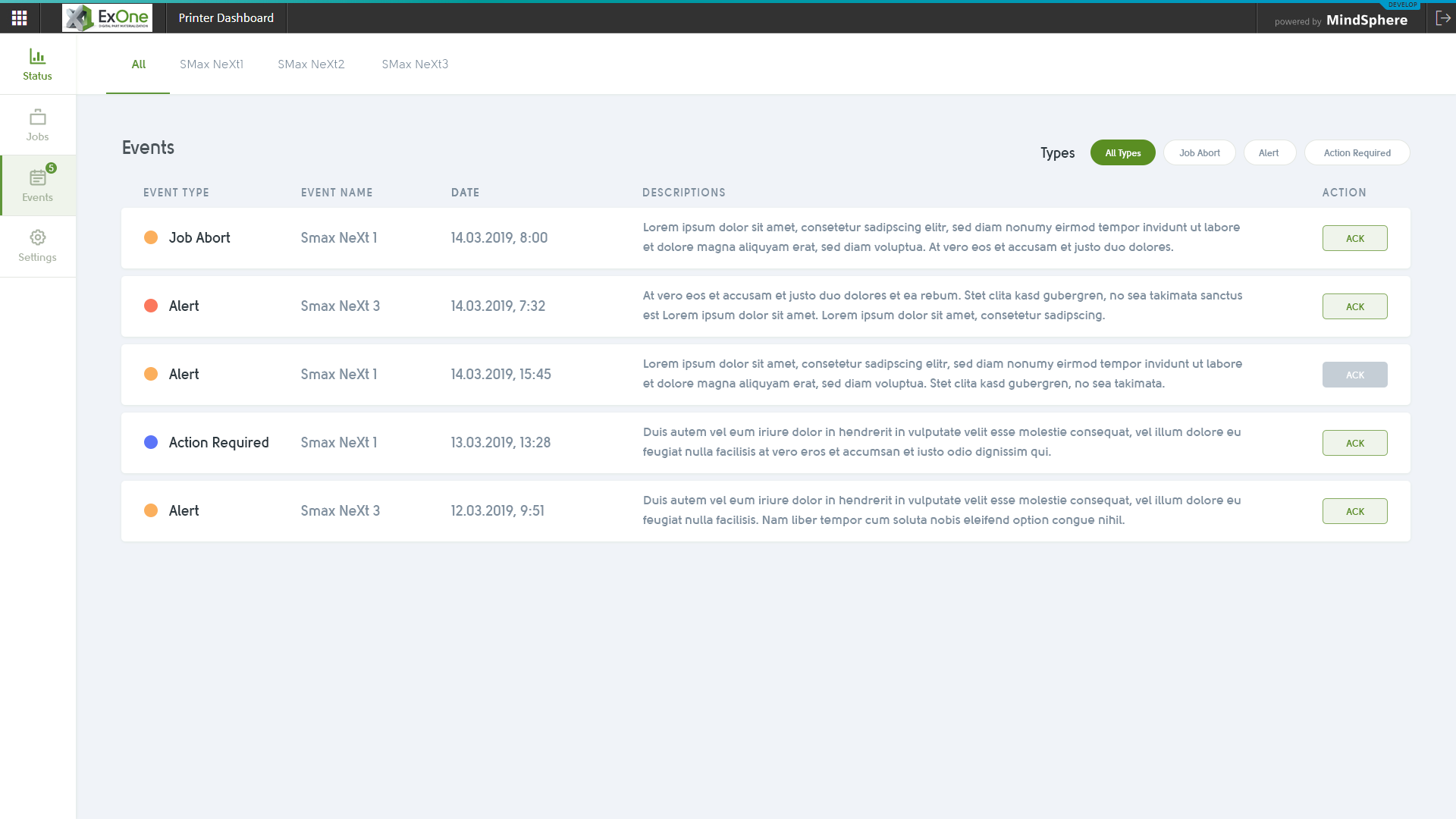

Real-time access to process data enables quality parameters to be monitored during printing – even remotely. In addition, notifications keep you informed about the current print status.

Improved quality assurance and analysis

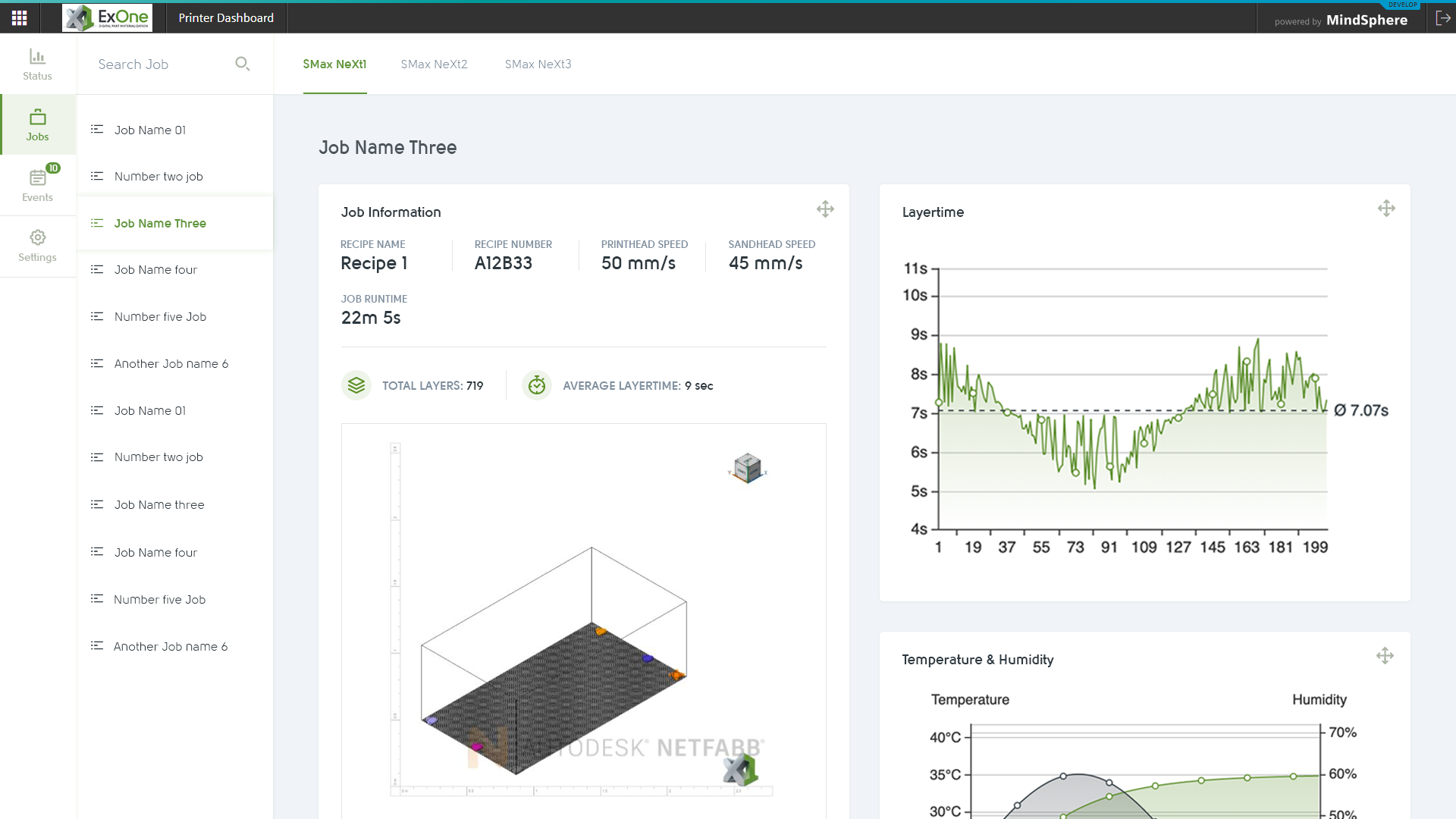

The analysis and comparison of already completed print jobs helps to evaluate data and allows to derive recommendations for action.

With the customers

Two customer segments were identified, for each of which one of the identified IoT-driven business models is particularly suitable.

In production

By knowing at all times whether an S Max Pro is in use, the additive manufacturing networks can now better share resources among themselves.