Quality assurance

swb

swb AG

Industry

Public utilities, infrastructure

Bremen, Germany

codestryke solution

IoT Application

The initial situation

Stadtwerke Bremen ensures a reliable and efficient supply of energy, drinking water and telecommunications in the cities of Bremen and Bremerhaven, as well as in the region of northern Germany. Since Germany mainly obtains natural gas from abroad, it must be constantly ensured that the quality and condition is at a stable high level. Especially in the north and west of Germany, the natural gas supply must be gradually switched from natural gas L (mainly from the Netherlands) to natural gas H (mainly from Russia and Norway) by 2030, as natural gas deposits in the Netherlands are becoming increasingly scarce. About 5 – 6 million private gas consumption installations will be affected by this changeover, about 230,000 of them in the Bremen area. Fluctuations in the gas supply can massively affect critical processes in industry, which can have a direct impact on product quality. It is therefore essential to detect fluctuations at an early stage and prevent potential consequences.

The solution

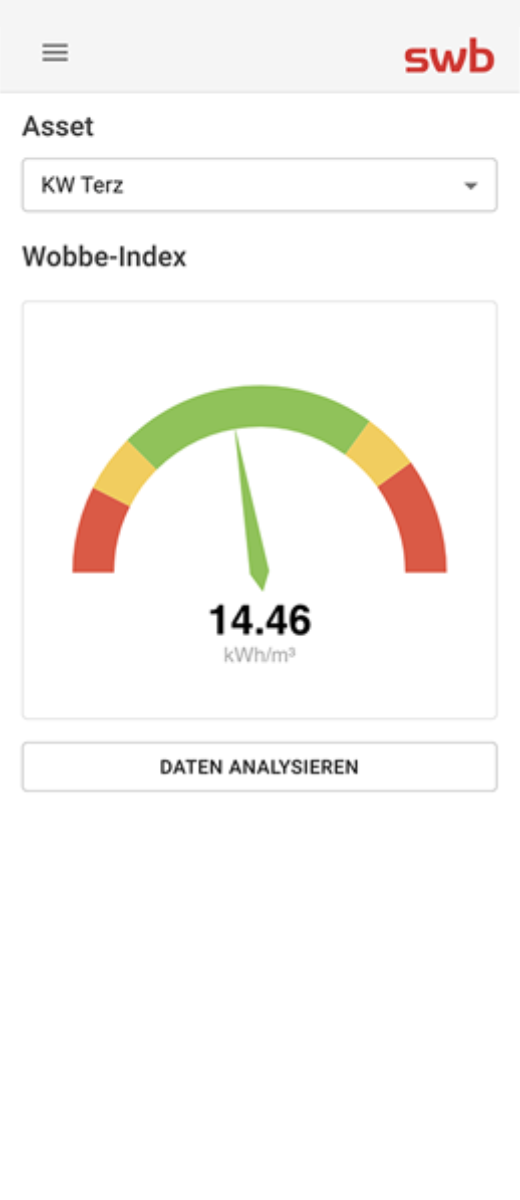

A Wobbe index measuring device was developed to detect fluctuations in the gas composition at an early stage and without constant manual checks by fitters. The Wobbe Index describes the burning behaviour of different gases and is therefore perfect for detecting different gases and thus fluctuations. In cooperation with Bright Sensors, swb therefore developed the WIM 3.0 (Wobbe Index Measuring Device), which, in combination with the BlueEye EX-D sensor, provides precise and up-to-date measured values for the Wobbe Index directly at the plants. With this, an inexpensive and compact complete solution has been developed that can detect fluctuations in the gas composition with the highest accuracy and in real time. In this way, production disruptions and quality losses that can be caused by fluctuations in the gas composition can be avoided in industry.

IoT application

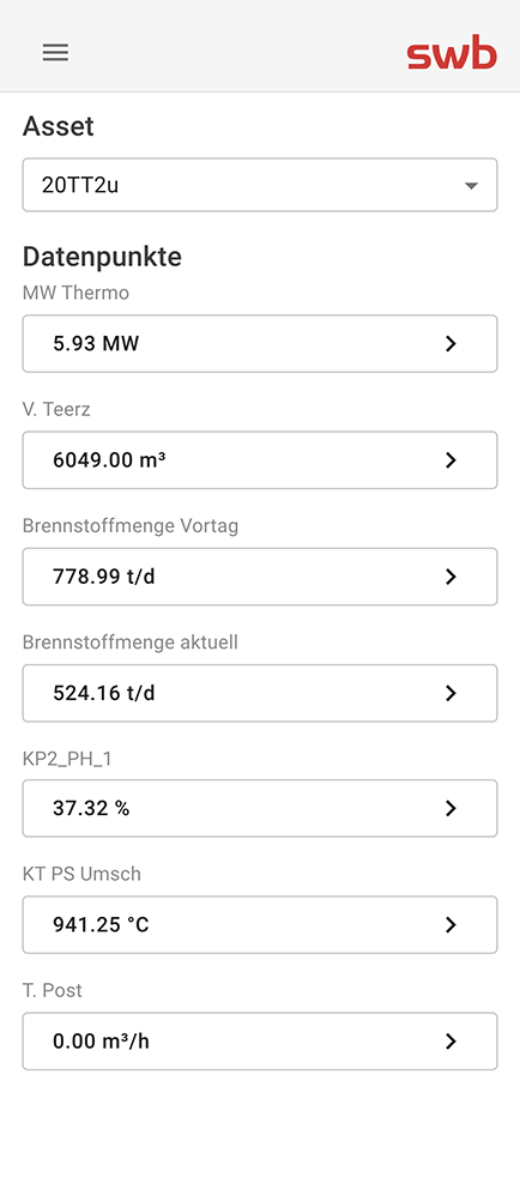

To make data processing and analysis even easier and more efficient, codestryke has developed a solution in the Siemens MindSphere universe that allows sensor data to be processed in a clear, logical and meaningful way. In the MindSphere app, valuable performance insights, historical data and precise real-time information can be accessed from anywhere. An important feature is the alarming of fluctuations, which enables remote analysis and diagnosis and makes the deployment of fitters or service staff even more efficient. This prevents quality fluctuations in the gas-based production processes and achieves massive savings by avoiding rejects.

Your benefits

Simple data analysis

Through the precise, complete and permanent transmission of sensor data, errors during processes can be detected and avoided at an early stage. This ensures product quality and minimises downtimes.

Easy installation

The system can be installed quickly, safely and easily in any working environment. This means that the conversion or set-up effort is manageable and fitters can work more efficiently.

Increasing efficiency

Maximum transparency and securing combustion ratios of air and natural gas can increase the efficiency of gas consumption plants. In addition, a contribution is made to the energy transition by allowing more “green gas” to be fed into the more flexible gas grid.